Mechanics & Hydraulic-Forklift Operator’s Daily Checklist

This Forklift Operator’s Daily

Checklist is very useful and user friendly and easy to understand for Forklift

Operators. This will provide you with all information and answers to the

questions you need to know and prepare and complete the checklist document such

as Test operating controls such as brakes, lights, horn, and steering wheel, check mast and overhead

guard for damage, examine

tire and fluid levels (hydraulic, brake, engine, fuel, and coolant), check for water, oil, or

radiator leaks, what

should I check daily on a forklift? What is the most done daily before using a forklift? What's the first thing you check on a

forklift? What are the important

rules to remember when operating a forklift? Free forklift operator daily checklist

printable, free

printable, forklift

daily checklist pdf, forklift

operator daily checklist doc, forklift

inspection checklist word, electric

forklift inspection checklist, and so on, etc.

The following checklist points must be made by

the machinery, Forklift, crane, or vehicle operator daily at the start of the shift.

Keep visiting the site regularly to download more crane, Forklift, machinery, or vehicle checklists in

editable and Word format.

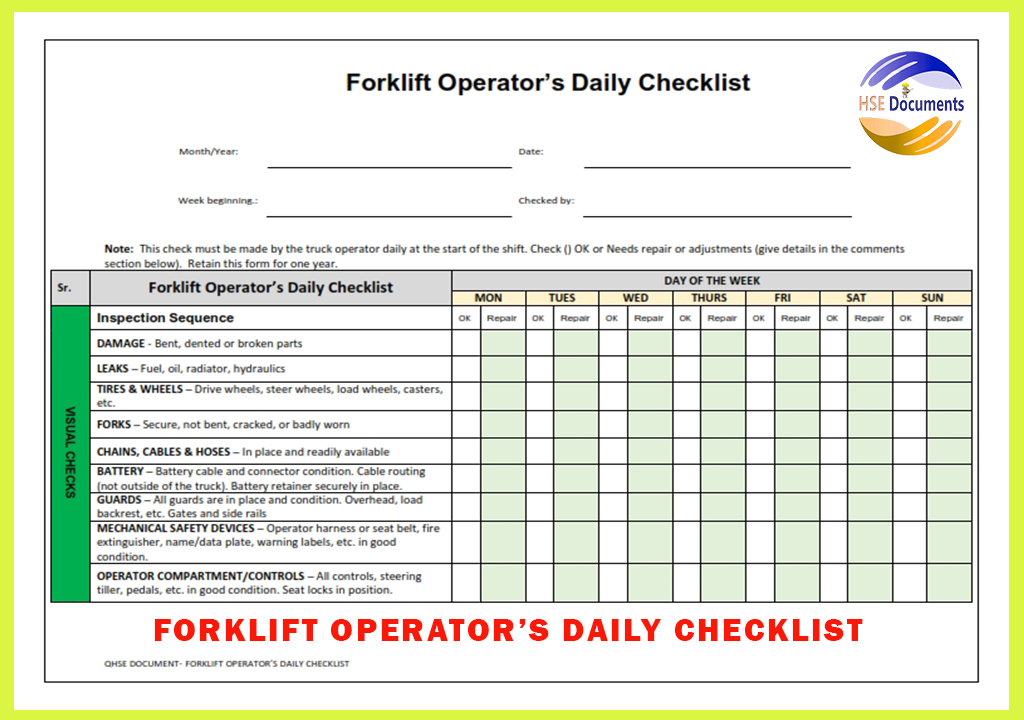

Forklift Operator’s Daily Checklist-Inspection Sequence

VISUAL CHECKS

1. DAMAGE – Bent, dented, or broken parts

2. LEAKS – Fuel, oil, radiator, hydraulics

3. TIRES & WHEELS – Drive wheels, steer wheels, load wheels, casters, etc.

4. FORKS – Secure, not bent, cracked, or badly worn

5. CHAINS, CABLES & HOSES – In place and readily available

6. BATTERY – Battery cable and connector condition. Cable routing (not outside of the truck). Battery retainer securely in place.

7. GUARDS – All guards are in place and condition. Overhead, load backrest, etc. Gates and side rails

8. MECHANICAL SAFETY DEVICES – Operator harness or seat belt, fire extinguisher, name/data plate, warning labels, etc. in good condition.

9. OPERATOR COMPARTMENT/CONTROLS – All controls, steering tiller, pedals, etc. in good condition. Seat locks in position.

OPERATIONAL CHECKS

1. POWER UP – Turn on the key. All indicators such as lights and alarms are working correctly.

2. POWER DISCONNECT – Cuts off all electrical power.

3. ELECTRICAL SAFETY DEVICES – Horn, audible signals, entry bar, flashing lights, indicator lights, etc. work properly

4. STEERING – No binding, no excessive play

5. BRAKES & TRAVEL CONTROLS – Check to brake & plugging distances while travelling slowly at first. If ok, then check at higher speeds. Acceleration is smooth, not jerky.

6. PARKING BRAKE – Seat, hand, or foot

7. HYDRAULIC CONTROLS – Test all hydraulic functions for smooth and proper operation and no unusual noise.

8. ATTACHMENTS – Function properly, no unusual noise, securely in place, especially removable attachments.

9. LIMIT SWITCHES – Travel limit, lift limit, tilt limit, safety reverse (walkies), etc.)

10. BATTERY CHARGE – Discharge meter in full green or 75% charge after raising forks.

11. WIRE GUIDANCE (SP and Turret Option) – Acquisition, tracking. Brakes set, alarm works, test by slowly driving off end aisle wire.

12. END AISLE CONTROL (SP and Turret Option) – The alarm beeps and the truck slow down or stops as programmed at the aisle end.

Caution

A. If the truck is found to require repair or in any way unsafe, or contributes to a dangerous condition, the matter shall be reported immediately to the designated authority, and the truck/vehicle shall not be driven or operated until it has been restored to a safe operating condition.

B. If during operation, the truck becomes unsafe in any way, the matter shall be reported immediately to the designated authority, and the truck shall only be operated once it has been restored to safe operating condition

C. Do not make repairs or adjustments unless specifically authorized to do so.

No comments:

Post a Comment